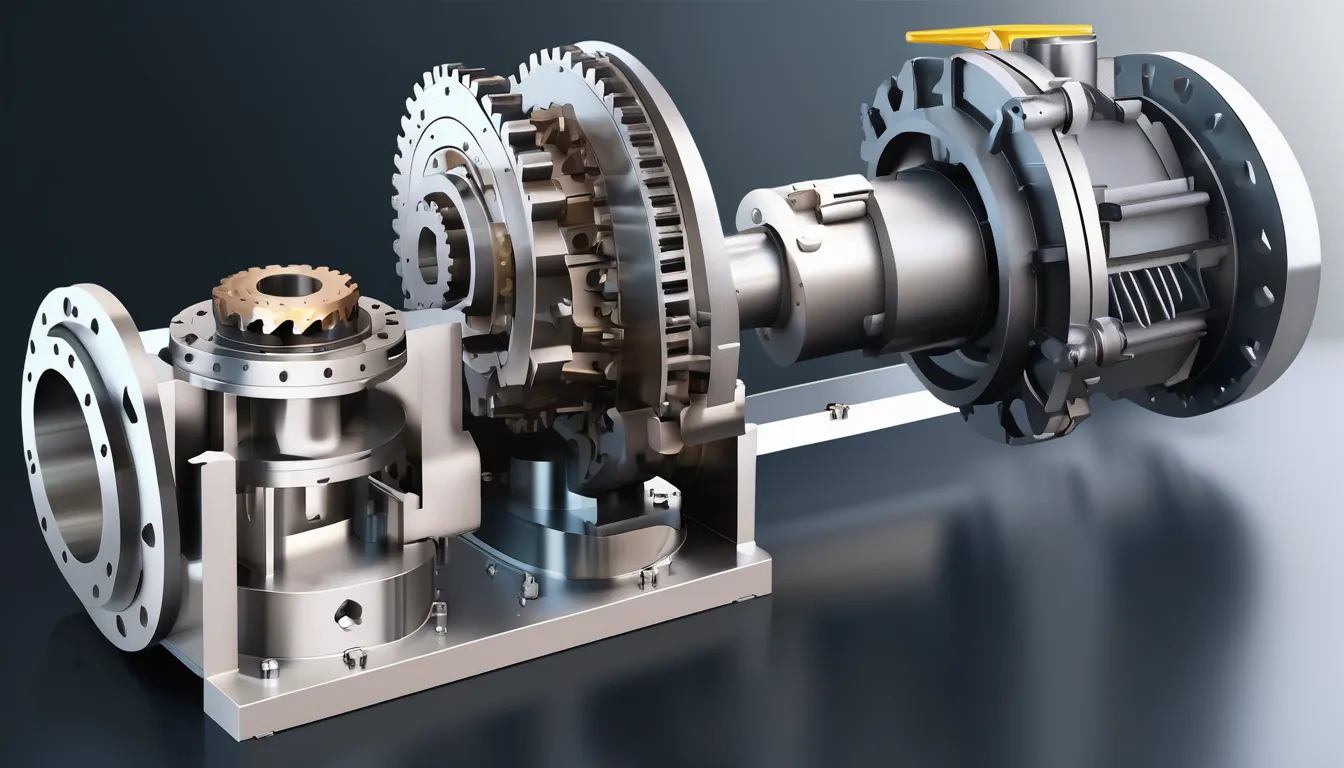

Common Myths About Helical Gearboxes Debunked

You might think helical gearboxes are noisy or that they demand excessive maintenance, but these are just a couple of the common myths that surround them. In reality, their design fosters durability and efficiency, often requiring minimal upkeep. You may also believe they’re difficult to install, but that’s not necessarily the case. Understanding the specifications and using the right tools can make the process straightforward. So, what’s the truth behind these misconceptions, and how can they impact your choice of gearboxes? Let’s explore further.

Helical Gearboxes Are Noisy

When you hear people say helical gearboxes are noisy, it’s time to set the record straight. Many misconceptions surround these devices, and noise is often one of the most exaggerated.

In reality, helical gearboxes are designed to operate more quietly than their spur gear counterparts. The angled teeth of helical gears allow for gradual engagement, which significantly reduces the impact noise during operation.

If you’re worried about noise, you should consider how installation and maintenance play crucial roles. Proper alignment and lubrication can dramatically decrease any potential sounds. If your gearbox is well-maintained, it’ll likely run smoothly and quietly, providing you with the efficient performance you expect.

It’s also worth noting that noise levels can vary based on the application and load conditions. In some cases, external factors like mounting surfaces or surrounding equipment can contribute to perceived noise levels.

Therefore, before jumping to conclusions about helical gearboxes being inherently noisy, take the time to evaluate your specific situation. With the right setup and care, you might find that they operate much more quietly than you anticipated.

They Require Excessive Maintenance

Some people believe helical gearboxes require excessive maintenance, but that’s a myth worth addressing. In reality, these gearboxes are designed for durability and efficiency, which means they often demand less upkeep than you might expect.

With proper installation and alignment, you can minimize wear and tear, allowing your helical gearbox to function smoothly for an extended period.

Regular maintenance mainly involves checking lubrication levels and ensuring there are no unusual vibrations or noise. By sticking to a simple routine, you can keep your gearbox in top shape without dedicating excessive time or resources.

Most manufacturers provide guidelines that help you determine the right maintenance schedule, so you don’t have to guess.

Plus, advancements in materials and technology have made modern helical gearboxes even more robust and reliable. Many users find they’re able to go long stretches without any significant issues, which further debunks the myth of excessive maintenance.

Helical Gearboxes Are Inefficient

For years, helical gearboxes have been misunderstood as inefficient components in mechanical systems. In reality, they’re known for their high efficiency and performance. When you consider the benefits they offer, it’s clear that the myth of inefficiency is just that—a myth.

Here are some key reasons why helical gearboxes are efficient:

- Smooth Operation: They provide quieter and smoother operation due to their design, reducing energy losses.

- High Load Capacity: Helical gears can handle higher loads, meaning you get more power without wasting energy.

- Less Heat Generation: Their design minimizes friction, which translates to lower heat generation and improved efficiency.

- Versatile Applications: They excel in numerous applications, making them suitable for both low and high-speed operations.

- Long Lifespan: Their durability means fewer replacements, reducing overall energy and resource consumption.

When you weigh these factors, it’s evident that helical Helical Gearbox es are anything but inefficient. Embracing their true capabilities can lead to enhanced performance and reliability in your mechanical systems.

Limited Applications for Helical Gearboxes

Many people believe that helical gearboxes have limited applications, but this is far from the truth. In reality, helical gearboxes are incredibly versatile and can be used in a wide range of industries. Their design allows for smooth operation and efficient power transmission, making them suitable for various applications.

Here’s a quick overview of some common applications for helical gearboxes:

| Industry | Application |

|---|---|

| Automotive | Transmission systems |

| Manufacturing | Conveyor systems |

| Robotics | Joint actuation |

| Aerospace | Flight control systems |

As you can see, helical gearboxes play crucial roles in multiple sectors. They’re frequently used in automotive transmissions for their ability to handle high torque loads while providing smooth gear changes. In manufacturing, they help power conveyor systems that move goods efficiently. In robotics, they enable precise movements, while in aerospace, they assist in controlling aircraft systems.

They Are Difficult to Install

Helical gearboxes are often thought to be tricky to install, but that misconception can lead to unnecessary hesitation.

In reality, if you follow a few straightforward guidelines, you’ll find the installation process is quite manageable.

Here are some key points to consider that can simplify your installation:

- Understand the Specifications: Familiarize yourself with the gearbox’s dimensions and requirements before you start.

- Use the Right Tools: Having the proper tools on hand can make a significant difference in ease and efficiency.

- Follow Manufacturer Instructions: Each gearbox comes with specific guidelines—stick to them to avoid complications.

- Check Alignment: Ensuring proper alignment prevents unnecessary wear and improves performance.

- Seek Expert Help if Needed: If you’re uncertain, consulting with an expert can save time and provide peace of mind.

Conclusion

In conclusion, it’s time to set the record straight about helical gearboxes. They’re not noisy, nor do they require excessive maintenance or compromise efficiency. You’ll find they’re versatile enough for various applications, and installation isn’t as complicated as some might think. By debunking these myths, you can fully appreciate the reliability and effectiveness of helical gearboxes in your projects. Embrace their benefits, and you’ll see just how valuable they can be in your operations!